In the age and environment of rapid advances in technology, it is often forecasted, quite comfortably, that the pulp and paper industry will see a lot of steady relationship between IT and process control technology.

Though process control departments in many paper mills used to be independent of IT, now the scenario has changed over time. Most paper mills have begun centralizing the two into one that shares systems, for instance virtualization technology. Interestingly, other new developments have been information integration, energy efficiency, and a wide usage of sensors within the pulp and paper industry.

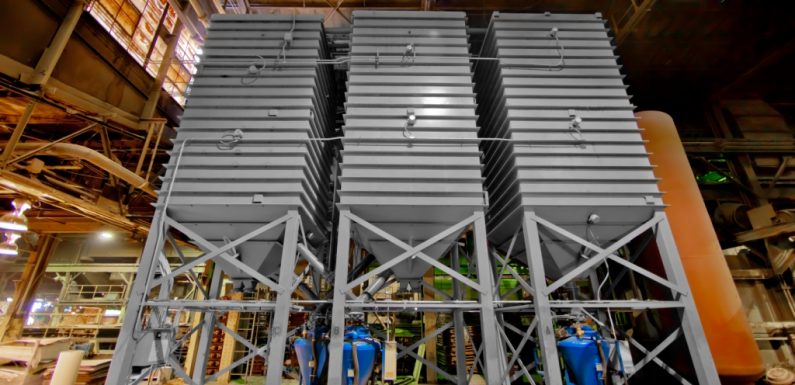

Virtualization is gradually picking up its own popularity in the paper industry. A large paper mill has perhaps about 260 personal computers and field workstations. A computer’s life span, including software and hardware, is about 3 years, resulting in a high maintenance cost for a paper mill. This is where virtual machines can step in to reduce cost in terms of purchase and maintenance, for plant control as well as in management areas.

Today, paper mills have managed to attain a real-time control over cost of production. Companies in this industry have begun implementing quality systems, data collecting systems, wide area networked inspection systems and the like. But these remain independent of each other.

This is where Honeywell’s Optivision manufacturing execution system MES steps in to innovate. It not only enables paper mills to access real-time data from the distributed control systems, but also creates several advantages by integrating these systems. Cost controls, new data support for better production decisions, and a more optimized production plan are other features that this system promises.

New sensor technology for the pulp and paper industries has always been an important research area for Honeywell, which has introduced many new sensors for these industries. For example, a Honeywell-equipped quality-control system (QCS) with faster camera sensors, higher frequency, and PPI measures uniformity, fiber orientation, and paper smoothness. These sensors can be mounted on a QCS to scan the paper back and forth to find potential defects.

Also, energy savings is an important issue for the pulp and paper industries. Let us say, by improving QCS control system performance, we can reduce the waste paper and other waste during production. MES (such as Honeywell Optivision) can improve slitting optimization and recheck efficiency, reduce 5% trimming, and save pulp and chemicals. Honeywell sensors can measure dehydration in press parts. To improve economy and reduce steam consumption, the paper mill tries to improve web dryness before moving the paper to the dryer. During the drying process, 90%-95% heat is used to vaporize the water in paper. A 1% moisture decrease means 5% heat saved. By monitoring the actual moisture, paper mills can decide if there is need to add more steam boxes to dry the paper.

(The higher the pulp temperature, the faster the dewatering speeds are. To improve productivity and reduce steam consumption, we can mount steam boxes on the wire and press parts of the paper machine, and heat the paper web using steam to improve the temperature and dewatering speed.)

This sensor can work independently in high temperatures (no cooling system is required) and other rigorous environments, without the need for cables or auxiliary components. The pulp and paper industries are starting to apply innovations, like these, as they look at how new technologies can achieve energy savings.

After all, resources are limited and only if we use them wisely can we achieve a sustainable development model, for generations to come.