Pulp and paper are huge consumers of energy. In fact, the world’s fifth- largest consumer of energy is the pulp and paper industry.

The World Resources Institute, a think-tank, put the industry’s CO2 emissions at about 500m tons worldwide in 2005. Comparatively, European companies are relatively green: the Confederation of European Paper Industries (CEPI), a trade association, says its members’ emissions were 46m tons in 2011. Pulp mills in under-regulated places also produce disgusting gunk.

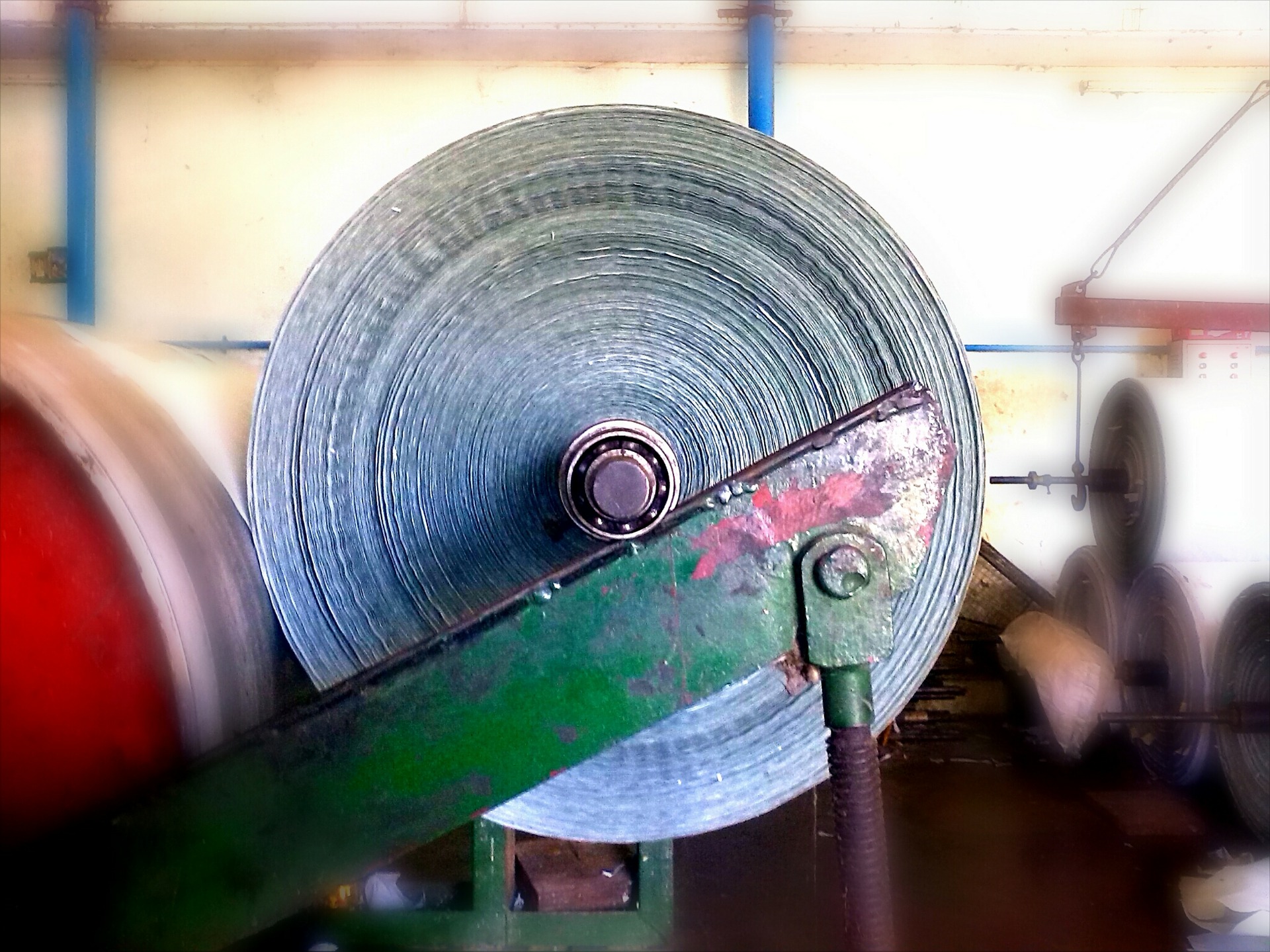

Paper is made by grinding wood chips mechanically to separate the fibers. It is also made by cooking wood chips with chemicals to remove the lignin, which binds the fibers together. You then dissolve the fibers in vast quantities of water and push them through a slit into a machine that squeezes out the water and dries the sheets.

CEPI decided to see if technological changes could yield more than just marginal improvements after facing demands for deep cuts in CO2 emissions. It set up two teams of scientists and businesspeople, each under a former chief executive (of Smurfit Kappa, the fourth-largest European papermaker, and Mondi, the fifth). The teams set up a common knowledge base because the idea was to test creativity, not proprietary information. They also sought ideas from outsiders with carbon-reduction programmes, such as Tata Steel.

The winning proposal would do away with all the grinding and chemical cooking that are an essential part of the existing process. Instead, it would utilize deep eutectic solvents to dissolve wood and separate out the lignin. These solvents occur naturally: plants produce them during droughts. They would essentially turn papermaking into a biochemical business, cutting primary energy use by 40%.

They would also generate useful by-products, such as pure lignin, a raw material for bulk chemicals, and a form of cellulose used in high-value chemicals.

One of the requirements of the project was that the ideas should add value, not just cut cost.

Drying the sheets now takes up most of the energy use in making paper. So making it without water would also cut energy consumption. The teams came up with two ways of doing that*. One would separate the fibers with steam (using less water). The other would suspend the fibers in a viscous fluid and then expel the fluid by modifying the viscosity around the fibers. This idea has been pinched from penguins. To escape from seals underwater, the birds release trapped air bubbles which form a thin layer of air around their plumage, reducing friction.

Even so, several lessons have emerged. They are:

• There are technological solutions to climate change

• Some of the ideas not only cut emissions but take energy-intensive firms into new areas like biochemicals, for pulp and paper

The pulp and paper firms managed to work together by confining their efforts to generic pre-competitive concepts, that is, basic breakthroughs.

The hope is that they will now compete to implement them.

*At the moment these ideas exist as pilot projects or in the laboratory, but not commercially. The most important test of their usefulness is therefore yet to be passed.