Pilot Paper Machine is an all time machine, because of its multi function or production capability. A pilot paper machine is capable of manufacturing a wide range of grades from lightweight tissue to heavy board. Industry has been depending on this model predominantly, even at the age of advanced and special paper making machines. Many paper making machine innovators are also focusing on the model and coming up with innovations in the model and the functionality.

Integration of Innovations in the Pilot Paper Machines

VPM 6

An entire paper manufacturing process from fiber to print can be tested on the Voith’s Pilot Paper Machine 6 or VPM 6 pilot paper machine, including experimentation with various fillers and chemical additives. This VPM 6 fiber design unit at the Heidenheim Paper Technology Center allows the dissolving of roll, bale or crumbly stock and then processed in cleaners, deflakers, fractioning machines and milling units. While, this stock can be treated with various fillers or chemical additives and therefore raw material formulas or raw material treatments can be optimized. Additionally, there is an evaluation of corresponding quality or runnability potentials of stocks and/or machine concepts. The noticeable qualities of this model are that

- The VPM 6 model is constructed for a design speed of 3000 m/min

- Paper production with a cut roll width of 800 mm and surface masses between 26 and 200 g/m2

- Due to its modularity, various machine concepts can be tested

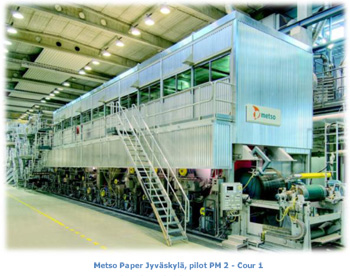

Rebuilt Pilot Paper Machine

Metso Paper rebuilt pilot paper machine – PM 2 for Rautpohja Paper Technology Center in Jyvskyl, Finland. The PM 2 model rebuild investment included

- A new press section

- A new OptiPress closed draw press section, a design with a totally new felt change system and eliminates the expensive cantilevering designs need

- Modernization of the dryer section

- This pilot PM 2 now has a 3,000 m/min design speed

- The felts can be pulled into the press is possible with a new-type of felt insertion equipment

- The ergonomics and safety have been raised to a new level with a cross-machine access way and other operator-friendly solutions

- The OptiDry Twin impingement drying unit, a system substantially reduces the number of dryer cylinders.

FEX – A complete pilot papermaking facility

An Innventia advanced paper machine, the FEX system is a complete pilot-scale papermaking facility for the pulp and paper industry. The pilot plant includes other important resources at pilot scale: a TMP refiner, a fractionation and screening system, a system for low consistency refining.

White water system in FEX is the basic design of the white-water system that is closed material-wise, by recovering material from the excess white water using a disc filter and mixing it into the thick stock. This is still unique for a pilot paper machine and all the volumes involved are minimized, to reduce the time to equilibrium and after a start-up of water filled system is within the range 60-90 minutes. While, the cleaned excess white-water flow is used to dilute the web in the press broke chest. This broke is not recirculated and instead fresh furnish is fed during the entire trial period. Therefore, the extensive measurements of white-water flow rates at different positions, combined with off-line analysis of the concentration of different material components, make it possible to evaluate material flow balances in some detail.

Experimental and Analytical Models

KCL’s Pilot paper machine is a substantial, analytical and experimental model in paper making. This paper machine is a flexible and an adaptable model allowing several kinds of materials that can be introduced to the system. The stock preparation system and paper machine allows controlled changes to the papermaking and can be examined and analyzed efficiently. The machine is equipped with a complete acquisition and reporting system for the main process parameters. The grammage, moisture and ash content are measured online and reported together with all main process parameters.

KCL’s pilot paper machine can be used for a wide range of different trials:

- optimization of papermaking furnish composition

- testing the effects of refining and screening on paper quality

- filler trials

- chemical testing

- wet web strength analyses

- testing totally new papermaking materials

- production demonstrations

- preparation of base paper for coating, calendaring and printing trials

KCL’s pilot paper machine is also equipped with hard nip online calendar, which can also be used in offline hard nip calendaring trials.

The following grades can be made on the pilot paper machine:

- news

- SC paper

- LWC base paper

- fine paper

- all single-layer board grades

Hence, the evolved dynamics in pilot paper machine is a very healthy supporting factor to the pulp and paper industry to produce different paper grades.